Smartec's Rotary Steerable System (RSS) represents a cutting-edge solution in the oil and gas drilling industry, designed to deliver precise directional control and enhanced efficiency in complex drilling environments. Built with advanced technology and engineered for optimal performance, Smartec's RSS Oil Drilling Equipment offers unparalleled reliability and accuracy. Tthe ideal choice for a wide range of drilling applications.

In the oil and gas industry, the demand for precise and efficient drilling technologies is paramount. The Rotary Steerable System (RSS) stands out as a revolutionary innovation.

This is transforming how we approach complex rock formations. RSS offers continuous rotation and precise control.

This has made it a critical component of modern oil drilling equipment. It enhances both the efficiency and accuracy of drilling operations.

A Rotary Steerable System (RSS) is a sophisticated drilling technology used in directional drilling. Traditional methods require rotating the entire drill string from the surface. This approach can be time-consuming and less efficient.

In contrast, RSS enables continuous rotation of the drill string. At the same time, it provides precise directional control of the drill bit.

RSS can “point the bit” in the desired direction while maintaining continuous rotation. This significantly reduces the risks associated with stopping and starting the rotation of the drill string. Such actions can cause damage to both the equipment and the wellbore.

We categorize RSS technology into two main types. These are push-the-bit systems and point-the-bit systems.

In push-the-bit systems, the drilling tool exerts lateral force against the borehole wall to steer the bit. Point-the-bit systems directly change the direction of the bit. This offers higher precision in challenging drilling environments.

One of the primary advantages of using an RSS is the enhancement of the drilling process. By allowing for continuous rotation, RSS minimizes the drag and torque typically experienced with traditional directional drilling methods.

This not only extends the life of the drill string but also improves the overall rate of penetration (ROP). Continuous rotation reduces the chances of getting stuck, which is a common issue in complex wells. This issue can lead to costly delays and damage to the drilling equipment.

RSS systems are integral in modern oil rigging operations. They allow for more precise wellbore placement, especially in horizontal and extended reach wells. This precision is crucial when drilling in formations that require exact wellbore placement to maximize production or avoid hazards.

An RSS typically consists of several key components. These components work together to steer the drill bit and control the drilling trajectory.

Top Drive: This device provides the necessary rotational force to the drill string, allowing for continuous rotation while drilling. A critical part of the drilling rig, this component works with the RSS to maintain precise directional control.

Mud Motors: Often combine Mud Motors with RSS technology. This combination enhances drilling efficiency and power.

They convert the hydraulic energy of the drilling fluid into mechanical energy to turn the bit. Mud motors are particularly useful in harsh downhole conditions. They provide additional power to drive the bit through hard formations.

Drill Pipe and Drill Bits: The drill pipe transmits the rotational force from the surface equipment to the drill bit. The choice of drill bits can vary depending on the formation type and drilling objectives. Common types include polycrystalline diamond compact (PDC) bits and tricone bits.

Rotary Table: The rotary table is another piece of equipment that rotates the drill string. Using top drives is less common in modern rigs.

Mud Pump and Mud Tank: The mud pump circulates drilling fluid (mud) through the drill string and back to the surface. The mud tank serves as a reservoir for storing drilling fluid. It also separates cuttings from the mud before recirculating it.

RSS is particularly effective in various types of oil drilling, such as:

Horizontal Drilling: Allows for precise placement of the wellbore in the target formation, maximizing exposure to the reservoir.

Extended Reach Drilling: Extended Reach Drilling enables the drilling of wells with long horizontal sections. This increases the reach of a single well from a surface location.

Complex Geological Formations: RSS provides the flexibility needed to navigate challenging formations, reducing the risk of wellbore instability.

The oil and gas industry continues to push the boundaries of exploration and production. The role of rotary steerable systems will become even more critical. RSS provides the ability to precisely control wellbore placement. It also maintains continuous rotation throughout the drilling process, helping companies reduce costs and increase efficiency.

Furthermore, Advancements in RSS technology include the integration of more sophisticated sensors. Real-time data transmission will provide even greater control over the drilling operation.

In conclusion, the Rotary Steerable System (RSS) represents a significant leap forward in drilling technology. By offering unparalleled control and efficiency, RSS systems are indispensable for modern oil drilling equipment.

Whether you're drilling in a conventional reservoir or navigating the complexities of an unconventional formation, RSS provides reliable performance. It ensures that your drilling operations are both efficient and effective. It paves the way for the future of oil and gas exploration.

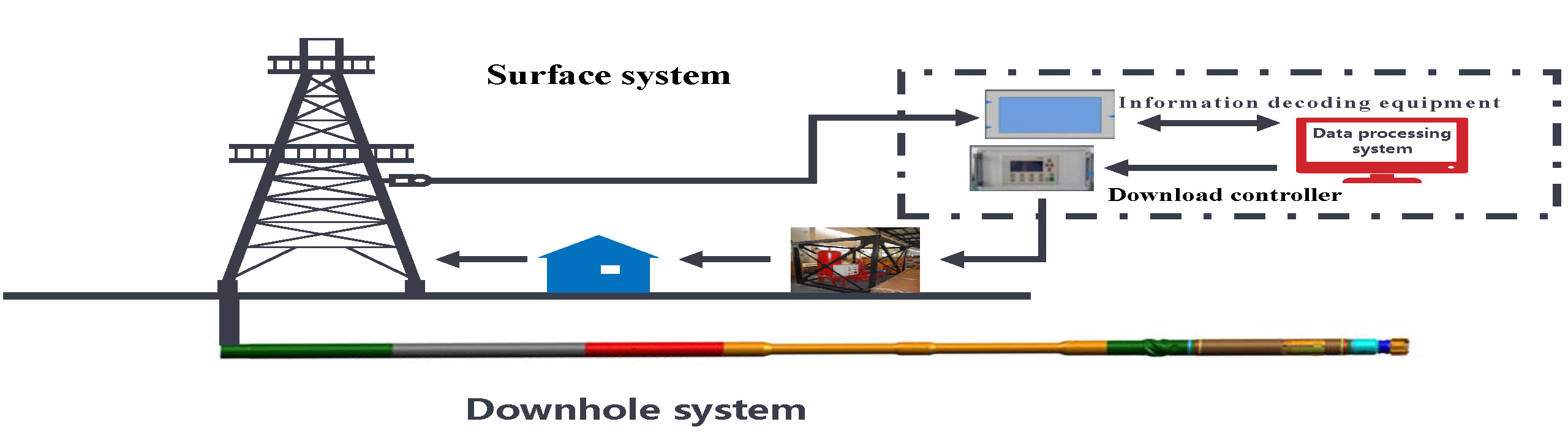

TEC RSS is mainly composed of Surface System and Downhole system.

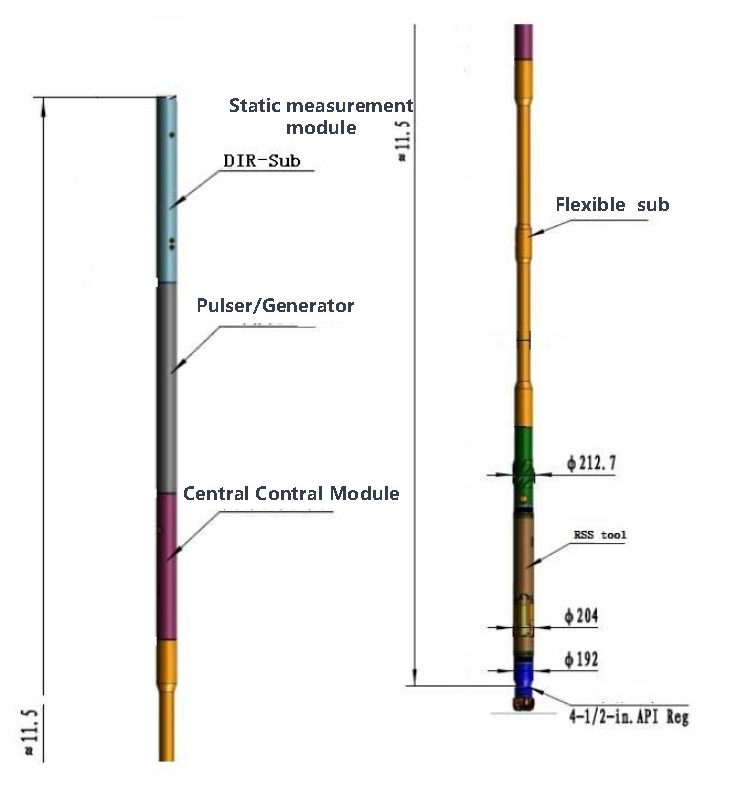

SMARTEC RSS Downhole system is mainly composed Static Measurement Module. Pulser & generator,Communication Module, Flexible sub and RSS tool.

Steering module structure design and manufacturing technology

Contactless power /information transmission technology

Micro-hydraulic drive and control technology

Mud pulse bidirectional communication technology

Downhole single-bus communication technology

High power turbine power generation technology

* With dual plunger/single plunger steerable tool interchange function.

* With zero-degree build-up function.

* With high-precision near-bit well deviation and azimuth gamma measurements.

* It has the function of high-precision tilt stabilization.

* High build-up rate, stable average build-up rate not lower than 11°/30m.

* The motor can be attached so as to improve the bit RPM not lower than 260r/min.

* It can be connected with formation parameter measuring instruments such as electromagnetic wave resistivity.

Tool OD :Φ178mm

Totle Length:11.2m/ 14.7m

Borehole Size:Φ215.9mm Maximum Tensile Load:2000kN

Maximum Torque to Failure:40kN•m

Maximum Hydrostatic Presure:20000 psi

Maximum Operating Temperature:150 ℃

Maximum Build-up Rate:15°/30m

MWD Well Deviation Measuremen accuracy:±0.1°

MWD Azimuth Measurement Accuracy:±1°

MWD Measuring Point Distance:10.5m

Near Bit Well Inclination Measurement Accuracy:±0.5°

Near Bit Azimuth Measurement Accuracy:±3°

Near bit Inclination Measuring Point Distance:1.1m

Gamma Accuracy:±3API@50API

Gamma Measurement range:0-500API

Gamma Measuring Point Distance:2.1m

Resistivity Measurement:4T2R

Resistivity Frequency:400kHz,2MHz

Resistivity Scale:0.01-2000Ωm

Resistivity Measuring Point Distance:8.3m

Mud Type:Water-base mud, Oil-base mud

High build-up rate

With Maximum build-up rate up to 15°/30m and stable build-up rate up to 15.2°/30m, the build-up capability is stable and reliable.

Multi-geological parameter measurement

The geological parameter measurement of electromagnetic wave resistivity, near-bit natural gamma, and near-bit azimuth gamma can be realized.

Zero-degree build up

With high-precision near-bit azimuth measurement and zero-degree build-up function. The

build-up azimuth control accuracy of the small well deviated section is better than ±5°.

——Conventional RSS

——15° High build-up RSS

——175℃ High Temperature RSS

——475 Slim Holer RSS

——475 High Temperature RSS

The current annual production capacity of the system reaches more than 50 strings a year, It has the processing capacity of various high-tech instruments and mechanical structural parts, and has the ability to produce, manufacture and test a full set of electronic circuits.

There are two assembly and maintenance bases in Guanghan and Beijing, The production capacity reaches more than 50 strings one year. with various high-tech instruments, produce, manufacture and test.

There are more than 50 on-site operators, and 20 on-site operation teams.

Contact: Mr. Chris Zhang

Phone: 86 180 6880 8880

E-mail: rotarysteeldrill@aliyun.com

Whatsapp:+86 18068808880

Add: Guangdong Province, China TianHe District, GuangZhou Num 899

We chat